When it comes to shipping and logistics, there are 10 different types of containers commonly used for shipping, including dry van, flat rack, open top, and refrigerated containers. Each type serves a specific purpose and is designed to meet various shipping needs and requirements.

There are several types of containers used in shipping, including standard dry containers, open-top containers, flat rack containers, refrigerated containers, etc. In the below table, we have mentioned container types, their sizes, and empty weights in tons.

|

Container Type |

Size (ft) |

Empty Weight (tons) |

|---|---|---|

|

Dry Storage Container |

10 to 40 ft |

2-4 tons |

|

Flat Rack Container |

20 to 40 ft |

2-4 tons |

|

Open Top Container |

10 to 40 ft |

2-4 tons |

|

Tunnel Container |

20 to 40 ft |

2-4 tons |

|

Open Side Storage Container |

20 ft |

2-4 tons |

|

Double Doors Container |

20 ft |

2-4 tons |

|

Refrigerated ISO Containers |

10 to 40 ft |

4-6 tons |

|

Insulated or Thermal Containers |

Varies |

Varies |

|

Cargo Storage Roll Container |

Varies |

Varies |

|

Half-Height Containers |

10 to 20 ft |

1-2 tons |

A dry storage container is a standard type of shipping container that is commonly used for the transportation of general cargo. These containers are sealed and weatherproof, designed to protect goods from the elements during transit.

Some features of dry storage containers:

Closed Structure: Dry containers have fully enclosed structures with solid walls, a roof, and double doors at one end. This closed design helps protect the cargo from external factors such as rain, wind, and sunlight.

Standard Sizes: Dry containers come in standard sizes, with the most common being 20 feet and 40 feet in length. The standard width is 8 feet, and the height is typically 8.5 feet. These dimensions are regulated by international shipping standards.

Cargo Security: The double doors at one end of the container provide easy access for loading and unloading. The doors are equipped with locking mechanisms to secure the cargo during transportation.

Versatility: Dry containers are versatile and suitable for a wide range of goods, including manufactured goods, consumer products, machinery, textiles, electronics, and other general cargo.

Stackable: Dry containers are designed to be stackable, which allows for efficient use of space on container ships and at container terminals.

Intermodal Compatibility: Dry containers are compatible with various modes of transportation, including ships, trucks, and trains. They can be smoothly transitioned between various modes of transportation without the necessity of unloading and reloading the cargo.

Weatherproof and Ventilated: While dry containers are designed to be weatherproof, they also typically have ventilation openings to prevent condensation inside the container, ensuring that the cargo remains in good condition.

International Standards: Dry containers conform to international standards set by organizations such as the International Organization for Standardization (ISO), making them widely accepted and interchangeable in global trade.

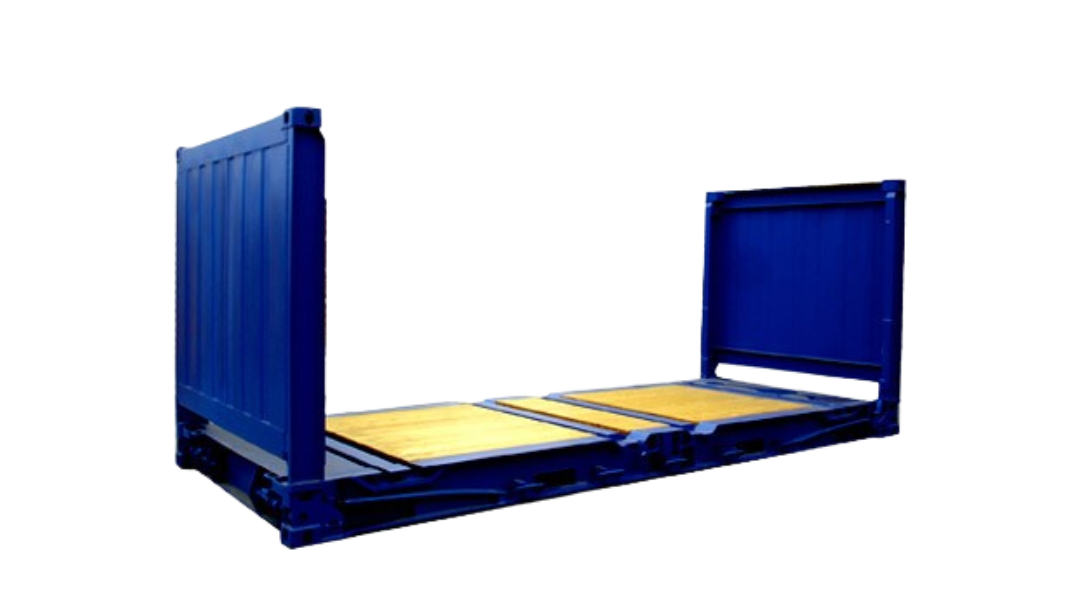

A flat rack container is a type of shipping container designed for the transportation of oversized or unconventional cargo that doesn't fit into standard containers. These containers have a flat, open structure without sides, allowing for easy loading and unloading of goods that exceed the dimensions of a regular container.

Some features of flat rack containers:

Open Structure: Flat rack containers have no side walls or roofs, providing an open platform for loading and unloading cargo from the top or sides.

Collapsible Ends: Many flat rack containers have collapsible or removable end walls. This feature allows for easier loading of cargo from the sides or top, especially when using cranes or other lifting equipment.

Securing Points: Flat racks typically have lashing rings, securing points, or other mechanisms to fasten and secure the cargo during transportation. This is crucial to prevent movement and damage during transit.

Available Sizes: Flat rack containers come in various sizes, similar to standard containers. Common lengths include 20 feet and 40 feet, and the width is typically 8 feet. The height may vary depending on whether the ends are fixed or collapsible.

Versatility: Flat racks are suitable for transporting heavy machinery, vehicles, large pipes, construction equipment, and other oversized items that cannot fit into a standard container.

Transport Modes: These containers can be used for both ocean and land transportation. They can be loaded onto container ships or transported by road or rail.

Specialized Types: There are specialized types of flat rack containers, such as those with bolster structures or platforms, designed for specific types of cargo.

An open-top container is a specialized type of shipping container designed with an openable roof to facilitate the loading and unloading of cargo from the top. This design is particularly useful for transporting goods that are too large to fit through standard container doors or that require overhead loading, such as heavy machinery, large equipment, or bulk cargo.

Features of open-top containers:

Removable or Openable Roof: Open-top containers have a roof that can be completely removed or hinged to provide easy access from the top. This design allows for the loading and unloading of cargo using cranes or other lifting equipment.

Securing Mechanisms: To ensure the safety of the cargo during transit, open-top containers are equipped with secure lashing points or rings. These allow for the proper securing of goods to prevent movement or damage.

Versatility: Open-top containers are versatile and suitable for a wide range of oversized or bulky cargo, including machinery, industrial equipment, construction materials, and other items that require top-loading.

Tarpaulin or Canvas Cover: In some cases, open-top containers may come with a tarpaulin or canvas cover to protect the cargo from the elements while still allowing top access. This cover helps shield the goods from rain, dust, and sunlight during transportation.

Standard Sizes: Open-top containers are available in standard sizes, with common lengths being 20 feet and 40 feet. The width and height dimensions adhere to standard container specifications.

Intermodal Compatibility: Like other standard shipping containers, open-top containers are compatible with various modes of transportation, including ships, trucks, and trains. It is simple to transport them between various modes without having to unload and reload the cargo.

Common Uses: Open-top containers are utilized in industries where cargo loading and unloading from the top are more practical. This includes construction, mining, and the transportation of oversized or irregularly shaped items.

ISO Container Standards: Open-top containers conform to international ISO container standards, ensuring their acceptance and interchangeability within the global shipping and logistics industry.

Ready to Sail Without Worries? Buy Marine Insurance!

Tunnel containers, also known as double-sided door containers or double access containers, are a specialized type of shipping container with doors on both ends, creating a tunnel-like structure. This design allows for easy access to the container from either side, facilitating efficient loading and unloading processes.

Features of tunnel containers:

Dual-End Access: The defining feature of tunnel containers is the presence of doors on both ends, creating a passageway or tunnel through the container. This design enables cargo to be loaded or unloaded from either end.

Versatility: Tunnel containers are versatile and suitable for various types of cargo. They are particularly useful for goods that may need to be accessed or unloaded from both ends, providing flexibility in handling different types of shipments.

Convenient Loading and Unloading: The dual-end access simplifies the process of loading and unloading cargo. It is especially advantageous for items that may have specific loading requirements or when access to both ends is necessary.

Secure Closure: The doors on both ends of the container are equipped with locking mechanisms to ensure cargo security during transportation.

Standard Sizes: Tunnel containers are available in standard sizes, with common lengths being 20 feet and 40 feet. The width and height dimensions adhere to standard container specifications.

Intermodal Compatibility: Like other standard shipping containers, tunnel containers are compatible with various modes of transportation, including ships, trucks, and trains. Cargo can be transferred between different modes seamlessly without requiring unloading and reloading.

Common Uses: Tunnel containers find applications in various industries where convenient access to cargo from both ends is advantageous. They are used in situations where loading and unloading may occur more efficiently through a dual-access system.

ISO Container Standards: Tunnel containers adhere to international ISO container standards, ensuring their acceptance and interchangeability within the global shipping and logistics industry.

Open-side storage containers, also known as side-opening containers, are a specialized type of shipping container with doors that open on one entire side, providing easy access to the entire width of the container. This design allows for convenient loading and unloading of goods, especially those that may have wide dimensions or require access to the entire length of the container.

Features of open-side storage containers:

Full-Length Side Opening: The main characteristic of these containers is that one entire side is designed to open fully. This creates a large, unobstructed opening along the side of the container.

Accessibility: Open-side containers are particularly useful for cargo that needs to be loaded or unloaded from the side, providing easy access for cranes. This feature is beneficial when dealing with long or wide items that may not fit through standard end doors.

Versatility: These containers are versatile and suitable for a variety of cargo, including machinery, construction materials, and other items with non-standard dimensions.

Secure Closure: The side doors are equipped with locking mechanisms to ensure the security of the cargo during transportation.

Standard Sizes: Open-side storage containers are available in standard sizes, with common lengths being 20 feet and 40 feet. The width and height dimensions typically adhere to standard container specifications.

Intermodal Compatibility: Like other standard shipping containers, open-side containers are compatible with various modes of transportation, including ships, trucks, and trains. They can seamlessly move between different modes of transportation without requiring the cargo to be unloaded and reloaded.

ISO Container Standards: Open-side storage containers conform to international ISO container standards, ensuring their acceptance and interchangeability within the global shipping and logistics industry.

Double-door containers are a type of shipping container that features doors on both ends, providing convenient access to the cargo from either side. This design facilitates efficient loading and unloading processes, especially when using forklifts or when there's a need to access items from both ends of the container.

Features of double-door containers:

Dual-End Access: The most distinctive feature of double-door containers is the presence of doors on both ends. This allows for easy access to the container from either side, providing flexibility in loading and unloading cargo.

Cargo Accessibility: Double-door containers are particularly useful when dealing with cargo that needs to be loaded or unloaded from both ends. This design simplifies the process of organizing and accessing goods within the container.

Versatility: These containers are versatile and suitable for a wide range of goods, including general cargo, machinery, equipment, and other items that may benefit from dual-end access.

Secure Closure: The doors on both ends of the container are equipped with locking mechanisms, ensuring cargo security during transportation.

Standard Sizes: Double-door containers are available in standard sizes, with the most common being 20 feet and 40 feet in length. The width remains consistent with standard container dimensions.

ISO Container Standards: These containers adhere to international ISO container standards, ensuring their acceptance and interchangeability within the global shipping industry.

Ship Smarter, Not Riskier: Secure Your Goods with Marine Insurance!

Refrigerated ISO containers, commonly known as reefers, are specialized shipping containers designed to transport goods at controlled temperatures. These containers are crucial for shipping perishable and temperature-sensitive products such as fruits, vegetables, pharmaceuticals, and certain chemicals.

Features of refrigerated ISO containers:

Temperature Control: The primary function of refrigerated ISO containers is to provide precise temperature control for the transported goods. They can maintain temperatures ranging from below-freezing to elevated levels, depending on the requirements of the cargo.

Insulation: Reefers are equipped with high-quality insulation materials to minimize heat exchange with the external environment. This insulation helps maintain the desired temperature inside the container.

Refrigeration Unit: Refrigerated containers are equipped with a built-in refrigeration unit. This unit is responsible for cooling or heating the air inside the container to maintain the specified temperature. It operates on electricity and is usually powered by the ship's electrical supply, a separate generator, or an external power source.

Temperature Monitoring Systems: Many reefers are equipped with advanced temperature monitoring systems. These systems allow for real-time tracking of the internal temperature and provide alerts if any deviations from the set parameters exist.

Air Circulation: Reefers have a ventilation system to ensure proper air circulation within the container. This helps maintain consistent temperatures throughout the cargo space.

Humidity Control: Some refrigerated containers come with features to control humidity levels, which is crucial for certain types of cargo, such as fruits and vegetables.

Power Sources: Refrigerated containers typically require a power source to operate the refrigeration unit. While on the ship, they are usually powered by the ship's electrical system. During overland transportation or storage, reefers may use a separate generator or plug into an external power supply.

ISO Container Standards: Refrigerated ISO containers conform to international ISO container standards, ensuring their compatibility with various modes of transportation, such as ships, trucks, and trains.

Insulated or thermal containers are specialized shipping containers designed to transport goods at controlled temperatures, protecting them from temperature variations during transit. These containers are commonly used for the shipment of temperature-sensitive products, such as pharmaceuticals, chemicals, food items, and other perishable goods.

Some features of insulated or thermal containers:

Temperature Control: The primary feature of these containers is their ability to regulate and maintain a specific temperature range inside. This is achieved through insulation materials and, in some cases, refrigeration or heating units.

Insulation Materials: Insulated containers are equipped with materials like polyurethane foam or other insulating materials that help minimize temperature fluctuations. The insulation provides a barrier against external temperature influences.

Refrigeration or Heating Units: Some insulated containers come with built-in refrigeration or heating units. Refrigerated containers, often referred to as "reefers," are designed to maintain a low temperature, while heated containers ensure that the cargo remains above a certain temperature threshold.

Temperature Monitoring Systems: Advanced thermal containers may feature temperature monitoring systems. These systems allow shippers to monitor and control the internal temperature remotely, ensuring that the cargo stays within the required range.

Ventilation: Depending on the type of cargo, insulated containers may have ventilation systems to control humidity levels and prevent moisture-related issues.

Specialized Designs: Insulated containers come in various designs to cater to different temperature-sensitive goods. For example, there are containers specifically designed for the transportation of pharmaceuticals, where precise temperature control is critical.

Power Sources: Refrigerated containers often require a power source, typically provided by the ship or a separate generator. Some containers have their power units, allowing them to operate independently.

Roll containers, also known as roll cages or roll trolleys, are typically used for the internal movement of goods within warehouses, retail stores, and other facilities rather than for shipping cargo over long distances.

They are not typically designed for ocean or international shipping like standard shipping containers. However, if you are looking for a container-like solution for transporting goods within a specific environment, a cargo storage roll container might be suitable.

Some characteristics of cargo storage roll containers:

Mobility: Roll containers are equipped with wheels, allowing them to be easily moved within a facility. They are often pushed or pulled by hand, but some may have additional features like handles for towing by a vehicle.

Collapsible Design: Many roll containers are designed to be collapsible or foldable when not in use. This feature is useful for saving space when the containers are empty or during storage.

Open Design: Roll containers typically have an open design with mesh or wire sides. This allows for easy visibility of the contents and promotes airflow, which can be important for certain types of goods.

Securing Mechanisms: Some roll containers have securing mechanisms, such as straps or locks, to keep the cargo in place during transport.

Variety of Sizes: Roll containers come in various sizes to accommodate different types of goods. Common sizes include 2-sided, 3-sided, and 4-sided containers, each offering different levels of accessibility.

Materials: Roll containers are often made of durable materials like steel or aluminum to withstand the rigors of handling within a warehouse or retail environment.

Don't Let Uncertainties Sink Your Business: Buy Marine Insurance!

Half-height containers are specialized shipping containers designed to transport cargo that require a lower profile or have a high center of gravity. These containers are constructed with a reduced height compared to standard containers, making them suitable for transporting heavy and tall items.

Some features of half-height containers:

Reduced Height: The most distinctive feature of half-height containers is their reduced height compared to standard containers. Instead of the typical 8.5 feet (2.59 meters), half-height containers are typically around 4.25 to 4.5 feet (1.3 to 1.37 meters) tall.

Open-Top Design: Half-height containers often have an open-top design, with removable or hinged tops that allow for easy loading and unloading of cargo. This design is particularly useful for items that need to be lifted from above, such as heavy machinery or oversized components.

Specialized Cargo: These containers are commonly used for the transportation of heavy and dense cargo, including minerals, machinery, bulk materials, and other items that may exceed the weight limits or dimensions of standard containers.

Secure Fastening Points: Like other types of containers, half-height containers are equipped with secure fastening points or lashing rings to ensure the cargo is properly secured and stabilized during transportation.

Common Sizes: Half-height containers are available in standard lengths, such as 20 feet and 40 feet, similar to standard containers. The width remains the same as that of a standard container.

When choosing the right type of container for shipping, it is important to consider several factors to ensure the safe and efficient transportation of your goods.

Some key points to remember:

Size and Weight of your Cargo: One of the first things to consider is the size and weight of your cargo. Different types of containers have different weight and size limits, so it is important to choose a container that can accommodate your goods without exceeding these limits.

Type of Goods: Take into account the type of products being shipped. For example, if you are shipping perishable items or goods that require special handling, you may need a refrigerated or insulated container.

Mode of Transportation: Consider how your goods will be transported. If they will be traveling by ship, you will need a standard shipping container. If they are traveling by air, you may need an air cargo container.

Destination: Consider the final destination of your goods. If they are traveling to a remote location or a region with limited infrastructure, you may need a container that is more durable and secure.

Cost: Finally, consider the cost of the container. Different types of containers come with different price tags, so it is important to choose one that fits within your budget.

Read More:

What is Marine Insurance Policy?: Benefits, and Coverage

Business Owner Insurance in India | Protect Your Business

Benefits of Group Health Insurance in India

In conclusion, there are various types of containers used in shipping goods across the globe. From standard dry containers to specialized reefer containers for perishable items, the shipping industry relies on a diverse range of containers to transport goods safely and efficiently. Choosing the right type of container is crucial to ensuring the successful delivery of cargo.